About hydraulic pressure and hydraulic valve

About hydraulic pressure and hydraulic valve

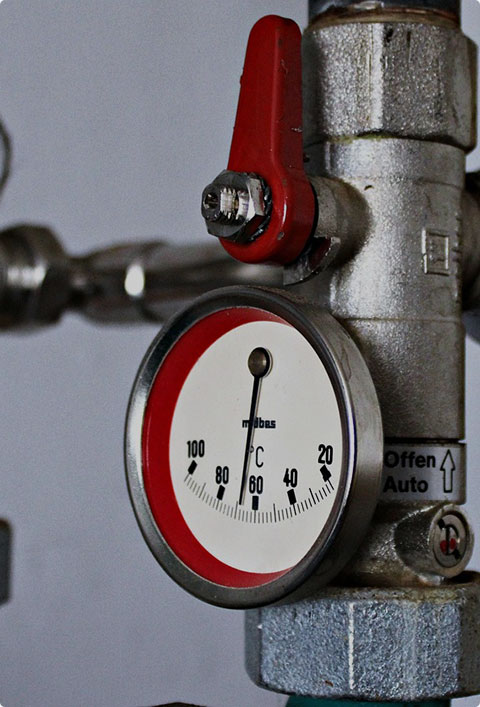

Hydraulic pressure is a technology that uses pressurized oil as a power source to move various things.

It is mainly composed of (1) hydraulic pump, (2) hydraulic valve, and (3) actuator. If you compare each to the human body, (1) hydraulic pump is considered to be “heart”, (2) hydraulic valve is considered to be “muscle”, and (3) actuator is considered to be “limb”. can do.

In other words, the hydraulic valve has the role of thinking and executing “arm force adjustment”, “arm swing speed”, and “arm swing direction” if it is compared to the human “arm swing” movement.

Considering an actuator such as an actual construction machine, the pressure, flow rate, and direction can be controlled, so it is possible to control the start / stop of the actuator, increase / decrease in speed, and operation order.

Type of hydraulic valve

There are only three types of hydraulic valves. (1) Pressure control valve, (2) Flow control valve, (3) Directional control valve.

(1) Pressure control valves are mainly “relief valves”, “counter balance valves”, and “sequence valves”.

(2) Flow control valves are mainly “flow control valves”, “throttle valves”, and “flow divider valves (flow dividing valves)”.

(3)Directional control valves are mainly “check valves”, “pilot valves”, and “shuttle valves”.

What is a “Flow divider valve”?

It is used to evenly distribute the oil flow through the hydraulic circuit into two parts. If you simply want to divide it into two parts, you can do it by simply using a bifurcated pipe, but even if there is a load difference, you can evenly distribute it by using a diversion valve and perform “tuned operation”.

As an example of use, since the two cylinders can be moved evenly (synchronized operation), it is used for a mechanism that evenly expands and contracts outriggers such as trucks with cranes and aerial work platforms. It is very easy to use, just install (install) it at a branch point in an existing hydraulic circuit, and no large-scale equipment is required.

In addition, the “fractional flow valve (deco valve)” can be reciprocated (going / returning) with one valve.